CIVIL WORKS GUIDELINES FOR MICRO-HYDROPOWER IN NEPAL

87

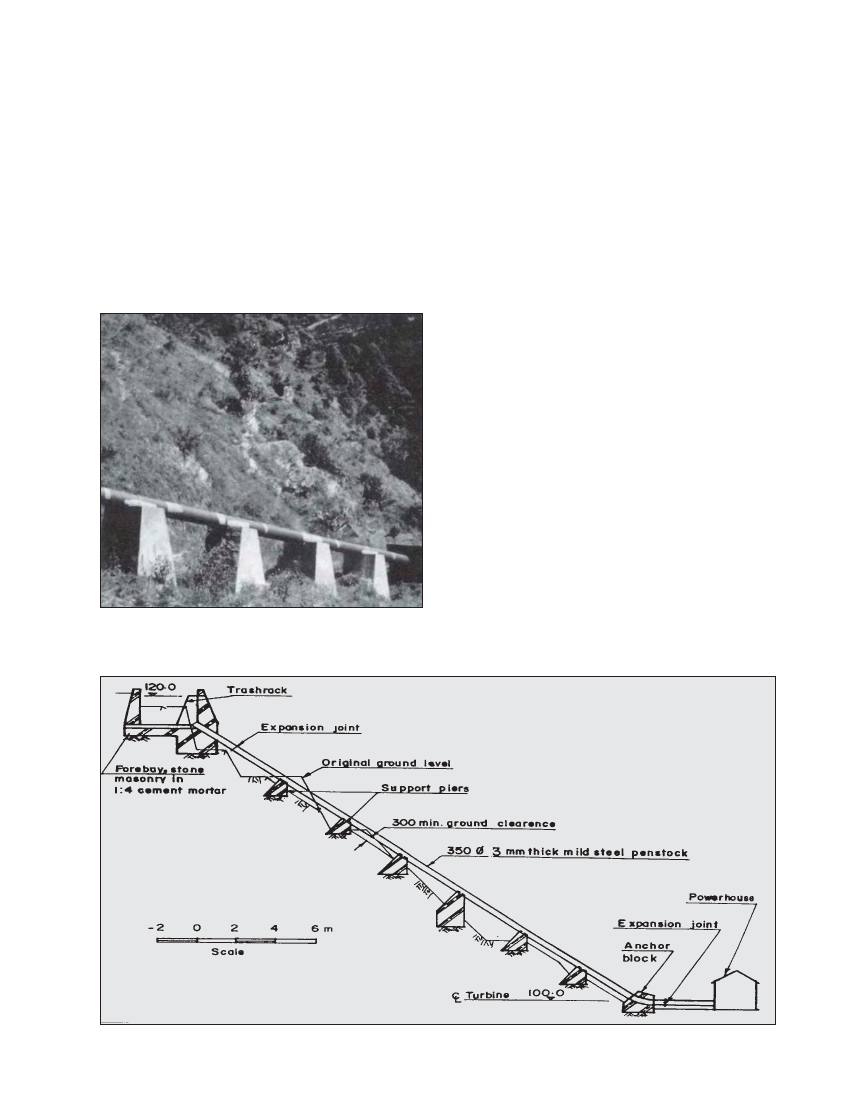

pipe, support piers and anchor blocks, and in case of pipe

bursts unstable slopes will cause further erosion and

landslides. Slope stability is discussed in detail in Chapter 9.

Other site specific conditions

Apart from the above criteria, there may be other site specific

conditions that dictate the penstock alignment. For example,

if the alignment crosses a local trail, this section should either

be buried or high enough above the ground such that people

and cattle can walk underneath. The Jhankre mini-hydro

penstock alignment is an example where a site specific

Photo 6.5 Penstock alignment high above the ground to

allow access for people and cattle, Jhankre mini-hydro

condition governed the penstock alignment. There is

cultivated land between the intake and powerhouse of this

scheme, so the penstock was aligned mostly along the edge of

the cultivated land. At one section this was not possible and

the alignment had to traverse the cultivated fields. Since it

was not possible to bury the pipes at this section (due to

downstream alignment), a few of the support piers were sized

to be 2 m high as shown in Photograph 6.5. This resulted in

a dear space of about 2.5 m under the penstock, which allows

farmers and cattle to walk underneath.

6.2.2 PROFILE OF THE SELECTED ALIGNMENT

Based on the site survey, a plan and profile of the penstock

alignment should be prepared at the design office as follows:

The ground profile should first be drawn using an

appropriate scale. Same scale should be used for both

horizontal and vertical lengths so that the bend angles are

true angles, which minimises the likelihood of errors. If

the alignment also has horizontal bends, then a plan view

should also be prepared to show horizontal bend angles.

Once the ground profile has been prepared, the penstock

pipe should be drawn on it such that the number of bends

is kept to a minimum. In general for above ground alignment

the support pier height should be minimised unless some

of them need to be increased to avoid small angle bends.

Similarly, excavation should be minimised for the buried

section unless deeper trenches are required at short sections

to avoid small angle bends. Optimising the alignment will

require some iterations. An example of a penstock profile is

shown in Figure 6.1.

For above ground penstock sections, a minimum ground

clearance of 300 mm is recommended to keep the pipe dry

and for ease of maintenance such as painting.

Figure 6.1 Typical penstock profile